|

|

In its infancy, the dawning automobile age began to gather different crafts under one roof, so to speak. The industrial engine designer, the wagon maker, and the coach builder found their combined skills being used for the production of early automobiles. Even the fine skills of the watch and clock maker - Henry Ford was skilled at watch making - could be adapted to car production.

The man who could bring the craft of coach building into modern car body production was Edward Gowan Budd. Budd was born in Delaware in 1870 and after finishing his education, worked in a number of machine shops, gaining valuable experience. At 18, he moved to Philadelphia where he studied mechanical engineering at the Franklin Institute. His interests were aimed at using pressed steel in place of the more traditional materials of wood, leather, and cast iron in manufacturing.

One of his first ventures into steel pressings was with the American Pulley Company. Having shown the company his models of pressed steel pulleys replacing their wooden and cast iron ones, they quickly saw the advantages in this new idea and the older materials soon became a thing of the past.

Budd then left to join the Hale and Kilburn Manufacturing Co. which was beginning to get involved with steel pressed products such as bowls, wheel hubs, and railway seats. The company had moved into railway carriage construction by the early 1900s designed by Budd, with the Pullman Co. moving over to this new design. They were lighter, stronger, and more fire resistant than their wooden predecessors.

Budd had also worked in developing arc welding techniques in conjunction with his pressed steel panels to further his ideas of all steel bodies for transport. After successfully applying this to the railroad industry, he looked next at the automobile industry and how his ideas might be applied there.

But, by and large, the car makers tended to stay with more traditional steel panels on wooden frame work. But one company listened to Budd’s ideas and arguments of his advanced concept. That was Hupp who turned to Hale and Kilburn for steelwork for their car bodies, though wood was still extensively used underneath the welded steel panels.

With this initial acceptance, Budd was keen to pursue the auto industry markets, but Hale and Kilburn viewed the car with some reservation. Was this new contraption just a passing fad: a toy for the rich perhaps? But, to Budd, it was the way forwards with this new industry.

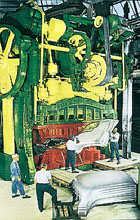

In 1912, with his son, E G Budd Jr., he set up the Budd Company with a staff of 12. Their only press to start production was kept in a tent at the rear of their small workshop. Joining them for technical development was Joe Ledwinks who shared their enthusiasm for all-steel bodies.

Whilst wood was still the favoured material for car bodies, two exceptions were Marmon and Pierce who had turned to cast aluminium as an alternative to wood. Thus Budd wasn’t alone with ideas of eliminating wood from car construction.

Fortunately for Budd, there was a new car company that could make use of his ideas as they had entered the market much later than the established names who had committed themselves financially, or contractually, to having wooden frames. This newcomer was Dodge Brothers. After considering Budd’s arguments, some of their 1923 Dodge Brothers cars had Budd all-steel bodies. While other makes were still considering the all-steel idea, Dodge had forged ahead in accepting this innovation, and moving the industry forwards and away from the craft of coachbuilding for mass produced cars.

|

|

|